Glasstec: HEGLA focuses on value creation and resource utilization

At Glasstec 2024, the HEGLA Group will focus on solutions designed to exploit the full potential of existing products.

Among the numerous live demonstration exhibits there are also some technological innovations that, for example, upgrade standard glass to bird protection glass.

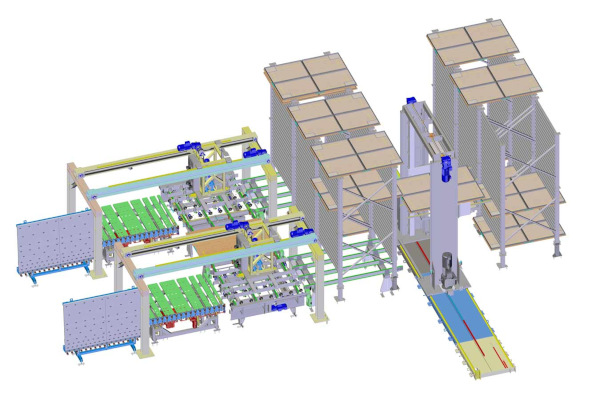

Sorting insulating glass: a continuous process

“With our new insulating glass sorting system, we have established a continuous transfer of insulating glass units from the production line to shipping in the desired order,” explains HEGLA Managing Director Bernhard Hötger. Until now, manufacturers had to switch from large formats to small formats in order to be able to stack everything neatly in their racks. The automated intermediate storage of insulating glass panes eliminates this strict dependency between production and shipping. For this purpose, up to four units are transferred to a transfer plate and stored in a drying tower. This achieves the same high quality as with the composite edge, so that the individual panes of an order and their successors can be put together. Once a batch is finally finished, the automatic or manual transfer of the shipping racks can be initiated in the correct order. “The decoupling of the process also opens up opportunities for further optimization,” emphasizes Bernhard Hötger. “For example, we can save set-up times when changing gas or sealing compound, depending on which insulation line we are working on.”

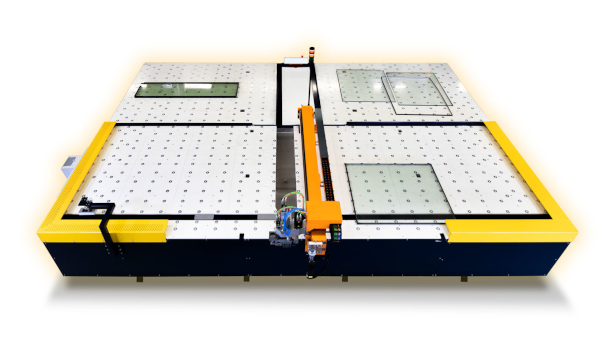

Sharing insulating glass for more sustainable use of resources

IG2Pieces, which was shown for the first time at the trade fair, focuses on the sustainable use of glass. After automatically recognizing the structure, dimensions and any coating, the system separates the insulating glass panes into their individual parts. “We wanted the shells and spacers to remain of perfect quality for the different applications,” explains Managing Director Dr. Heinrich Ostendarp, who is responsible for technology and development. Once the insulating unit has been separated, many possibilities open up. Disposal of the different types promises higher purchase prices than mixed containers. And the environment benefits too: In the spirit of the circular economy, the glass is returned to the float shell, which sustainably reduces CO2 emissions. Individual panes without defects can be used again, for example for cutting to smaller formats or for other applications (e.g. shelves).

Depending on the format and structure of the insulating glass, it can also make sense to use it to repair freshly produced units. For example, with panes that have been supplied (expensive laminated glass, prints or high-quality coatings), rework saves lead times and additional costs. “Our automatic separation system increases the efficiency of a process that was previously heavily dependent on the skill and speed of our employees,” says Dr. Heinrich Ostendarp.

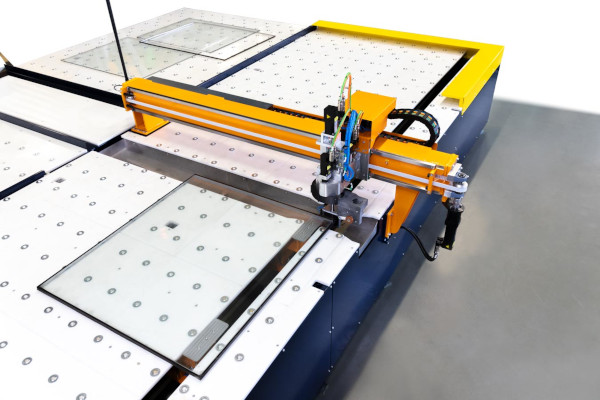

Added value: Sustainable bird protection

The new BIRDFriend mobile is now available at HEGLA boraident. With this portable solution, windows and facades can also be retrofitted with a bird protection pattern. Using a laser printing process, ceramic particles are transferred from a transfer tape directly onto the glass surface. This creates a uniform dot geometry that is barely visible to the human eye. However, birds register them as an obstacle that they cannot miss. To ensure maximum protection even when the sun is in an unfavorable position and there is strong reflection, the print is applied to the outside of the glass (position 1). The pattern has a threefold effect: the distance between the dots signals to birds that this is an area that they cannot fly through. In addition, the pattern interrupts deceptively real reflections from trees and the changed light reflection and refraction serves as an additional warning signal. This protects nature and permanently avoids the need to replace existing glass panes.

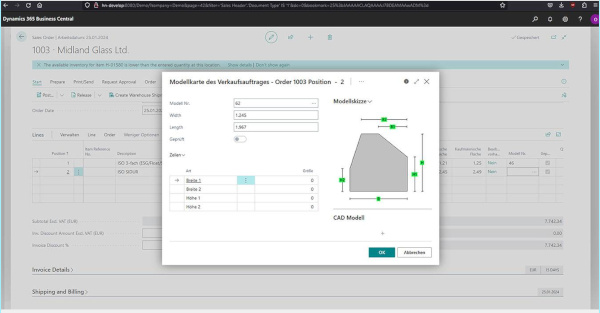

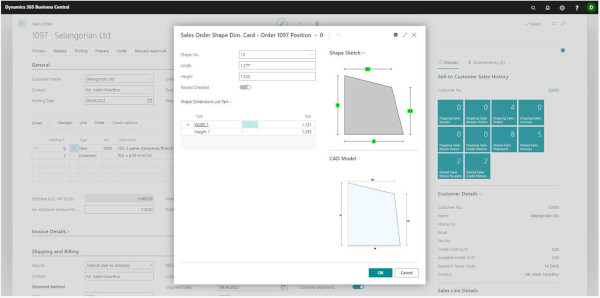

New ERP system: More data transparency, more add-ons

The first of our customers are already using the new HEGLA-HANIC ERP. At Glasstec, we can provide a clear insight into this software for the first time. “This new concept is a huge step for us and goes far beyond normal updates and changes,” emphasizes HEGLA-HANIC Managing Director Dr. Jan Schäpers. “The new system combines the strengths of our existing software with the advantages of Microsoft Dynamics 365 Business Central.” Users work with familiar interfaces, the software works on all devices and can even be scaled across departments and locations. In addition, Dynamics AppSource offers a range of additional apps for extended functions, such as defined interfaces for the full integration of Excel, Outlook and other Office 365 tools.

In addition, the HEGLA Group will be presenting other systems live at its exhibition stand: the ReMaster, the ProLam LSR cutting system for laminated safety glass and a float glass trimming system with a vertical residual system, as is common in North America. In addition, HEGLA will be exhibiting its refurbished vacuum lifters from Kretzschau for visitors to the Glasstec to view.

“We are looking forward to Glasstec and the big reunion in Düsseldorf,” says HEGLA Managing Director Bernhardt Hötger. “The many interesting discussions, the variety of innovations on display and the unique atmosphere make this trade fair a unique experience every time.”

You will find HEGLA, HEGLA Kretzschau (vacuum lifting devices), HEGLA boraident and HEGLA-HANIC in Hall 16, Stand A60.